At Wrazen Machining & Design I offer a variety of services for you machining and designing needs. Below are just some of the services that I offer. If you have any additional needs, please feel free to contact me. I look forward to helping you with your Mechanical and Design needs!

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with Ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobile, motorcycle, and bicycle parts. The powder coating process was invented around 1945 by Daniel Gustin US Patent 2538562.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with Ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobile, motorcycle, and bicycle parts. The powder coating process was invented around 1945 by Daniel Gustin US Patent 2538562.

I offer professional Powder Coating services in numerous colors. Powder coating is one of many coloring processes for industrial purposes.

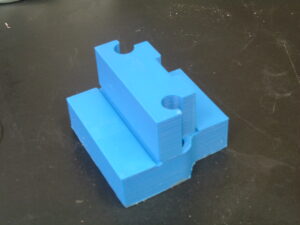

3D Printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. The term "3D printing" can refer to a variety of processes in which material is joined or solidified under computer control to create a three-dimensional object, with material being added together (such as liquid molecules or powder grains being fused together), typically layer by layer.

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. The term "3D printing" can refer to a variety of processes in which material is joined or solidified under computer control to create a three-dimensional object, with material being added together (such as liquid molecules or powder grains being fused together), typically layer by layer.

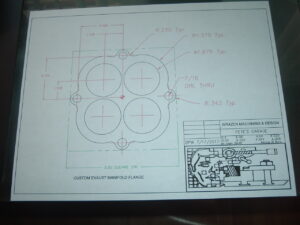

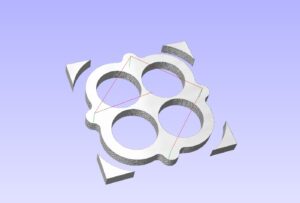

Reverse Engineering

Reverse engineering provides manufacturers with information about the design of a product or component. When done successfully, reverse engineering gives you a virtual copy of the blueprint that went into the original design.

Reverse engineering provides manufacturers with information about the design of a product or component. When done successfully, reverse engineering gives you a virtual copy of the blueprint that went into the original design.

Reverse engineering is perhaps the most accurate way to recreate the designs for items that went out of production decades beforehand. In cases where the original blueprints are long since lost or destroyed, reverse engineering is perhaps the only way to bring such products back to life. If you can obtain a working model of an old product, you can typically trace the steps of its design and use those insights to construct a new model, repair a part or improve future products.

Reversed Engineering Example Video

Precision Prototypes

A prototype is an early sample, model, or release of a product built to test a concept or process. A prototype is generally used to evaluate a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one.

A prototype is an early sample, model, or release of a product built to test a concept or process. A prototype is generally used to evaluate a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one.

Are you looking for a professional prototype for your design idea? I can help by manufacturing a professional prototype from your blueprints and drawings.

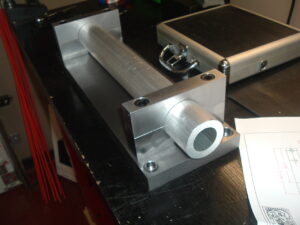

Precision Machining

Precision machining is a process that removes excess, raw material from a work-piece, while holding close tolerance finishes, to create a finished product. ... This process involves cutting, milling, turning, and electrical discharge machining, and is generally performed using Computer Numerical Control (CNC) equipment.

Precision machining is a process that removes excess, raw material from a work-piece, while holding close tolerance finishes, to create a finished product. ... This process involves cutting, milling, turning, and electrical discharge machining, and is generally performed using Computer Numerical Control (CNC) equipment.

I use modern CNC (Computer Numerical Controls) milling in our precision machining. I also provide precision 3 axis and 4 axis milling.

If you would like a quote for any of my services, please contact me and I will respond as soon as possible. You may also call me at 716-418-6494 or email me at [email protected]. I look forward to helping you with your machining and design needs!